The New Jersey Manufacturing Extension Program (NJMEP) is a branch of the National Institute of Standards and Technology’s Hollings Manufacturing Extension Partnership (MEP). This network, which supports U.S. manufacturers across all 50 states and Puerto Rico, aims to assist these businesses in increasing profitability and becoming more globally competitive.

For over 10 years, we have worked with NJMEP, entrusting it to provide the various consulting and training services we need.

MAC Products was proud to be featured on the NJMEP site and YouTube channel recently. You can read the article or watch the video to learn more about MAC and the role we play in New Jersey’s business world.

[ Embed Video Here in Blog ]

MAC: A Key Player in the NJ Manufacturing World

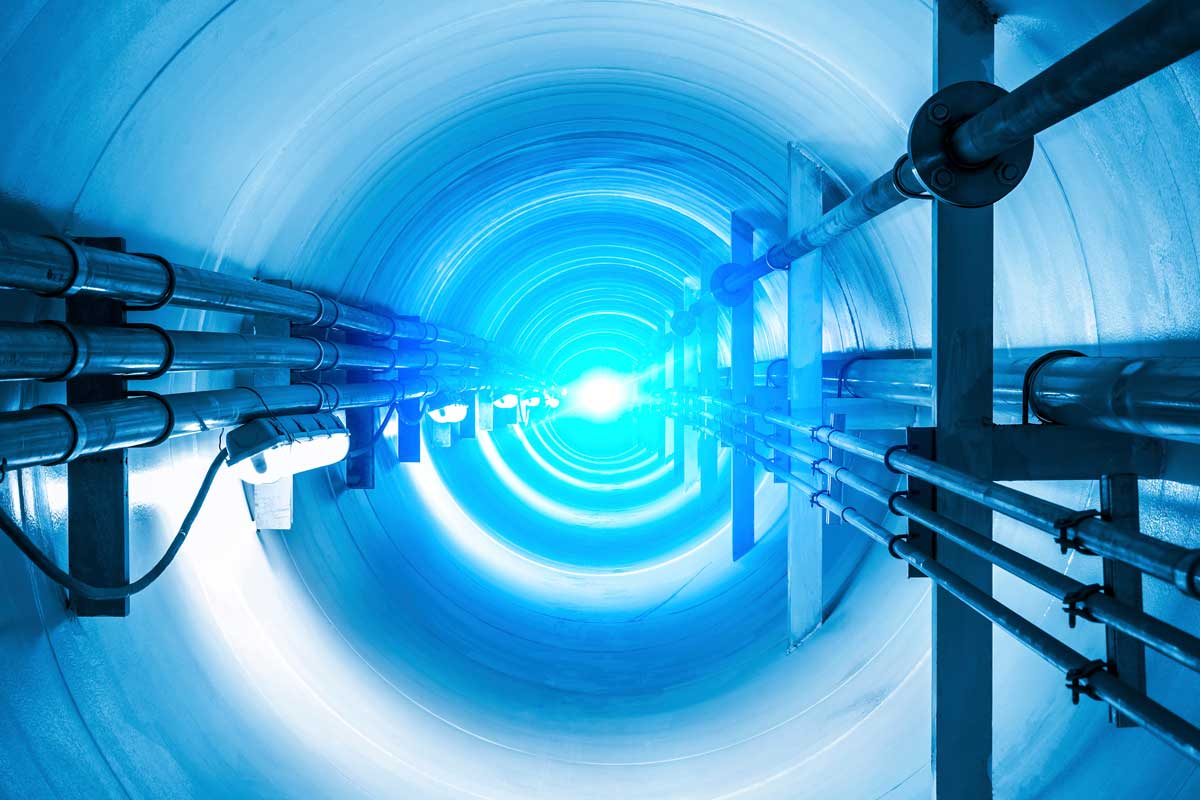

Since our company was started by founder Ed Gollob and just two employees in 1968, MAC has become a trusted name in manufacturing components primarily for the electrical utility and electrified mass transit industries throughout North America.

Since our beginnings more than 55 years ago, MAC has expanded to a company with over 100 employees and a 4.5-acre fully integrated complex. We are proud of our New Jersey roots, and that’s why we are still based here in South Kearny.

As a family-owned and -operated firm, MAC’s leadership spans three generations.

‘We Don’t Do Easy’

This is our company’s motto, and we like to think it encapsulates how we do things. “Personal” and “honest” are the key words to describe how we do business.

Most of our products are manufactured to order, ensuring that our clients have precisely what they need right when they need it. After all, our clients do not come to us when things are easy. They come to us when they have a challenge—whether it is a tough engineering problem, a hard-to-find component, or a fast turnaround time. Our job is to find solutions for those challenges, and our services include not just design and manufacture but also installation and staff training.

Our People Grow With Our Business

NJMEP interviewed MAC President Eddie Russnow, who has been with the company since 1990. Coming from a background in international finance, Eddie never expected to build a career in the manufacturing world.

However, at MAC, we believe in developing our people and empowering them to grow with the business and build a rewarding career. “Everything I did, I learned on the job,” says Eddie. We believe in upskilling and reskilling our team members throughout their time with us, giving them opportunities to advance within the organization.

In a world where there is an expanding and increasingly challenging skills gap, it is vital that we communicate effectively with our staff, get their buy-in to the way that we do things, and support them to become the best that they can be.

Adapting to New Technologies

In the early days, we used a lot of manual equipment, some of which is still in use today. However, we have also taken steps to extend the life and enhance the capabilities of this equipment while adopting and adapting to new and innovative technologies.

Sometimes this means taking a leap of faith, taking a risk, and trying something new. Trying out new machines, technologies, and approaches allows us to stay on the leading edge of our industry and adapt to the ever-changing needs and demands of our customers.

The Digital Future of Manufacturing

NJMEP asked us what we believe the future of manufacturing will be as the digital age progresses and technologies become ever more advanced.

Industry 4.0, or the Fourth Industrial Revolution—the next phase in the digital transformation in our field—calls to mind technologies such as robotics and automation tools. However, we believe that a key and often forgotten element will be software.

Eddie recalls Ed Gollob, the founder of MAC, teaching himself how to use the first software suite the company bought and then bringing the engineering team into his office to demonstrate it to them. This willingness to try new tools, to learn, and to embrace a changing market landscape is one of the keys to MAC’s success so far and, we believe, will also be what carries us successfully into the future.

Making the Most of Available Resources: NJMVP

The New Jersey Manufacturing Voucher Program provides equipment grants to enable companies to expand their capabilities through investing in technology. We were fortunate to receive a grant to purchase a CNC ironworker, which will improve the throughput of our fabrication of various components.

If we could offer one piece of advice to our colleagues throughout the manufacturing industry, it would be this: Make the most of the resources available to you. From our work with NJMEP to our grant from NJMVP, these partnerships have helped our company thrive for the past five decades.

Related Posts

Understanding Substation Circuit Breakers: The Heart of Reliable Power Distribution

Unveiling the Versatility of Pipe-Type Cable Connectors in Modern Engineering