Custom Copper Busbar Solutions for a New Mining Locomotive

Our client was manufacturing an electric locomotive prototype to be deployed in a large-scale operation for a mining company. The first of its kind, the vehicle was designed to be fully electric and battery-operated.

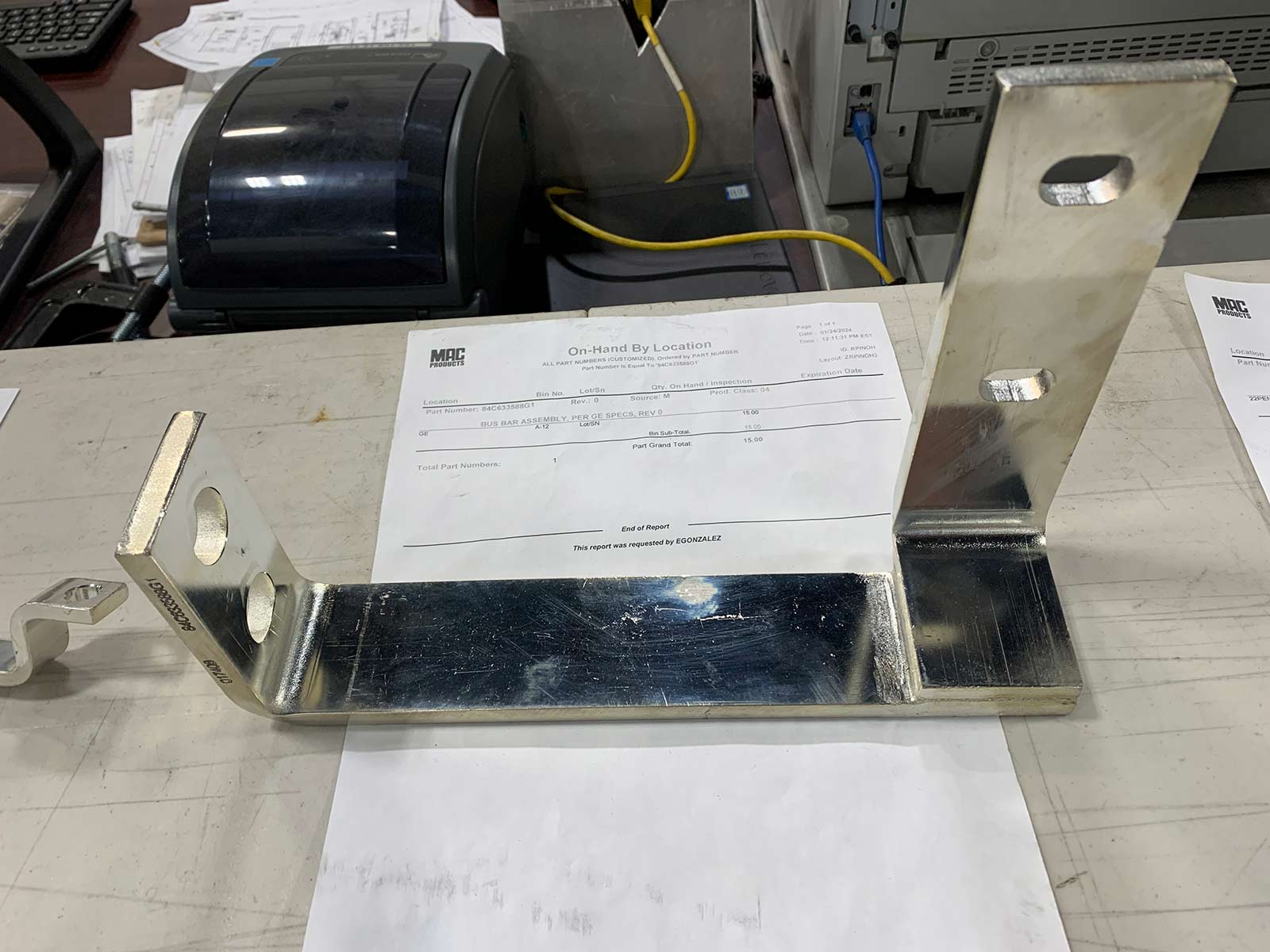

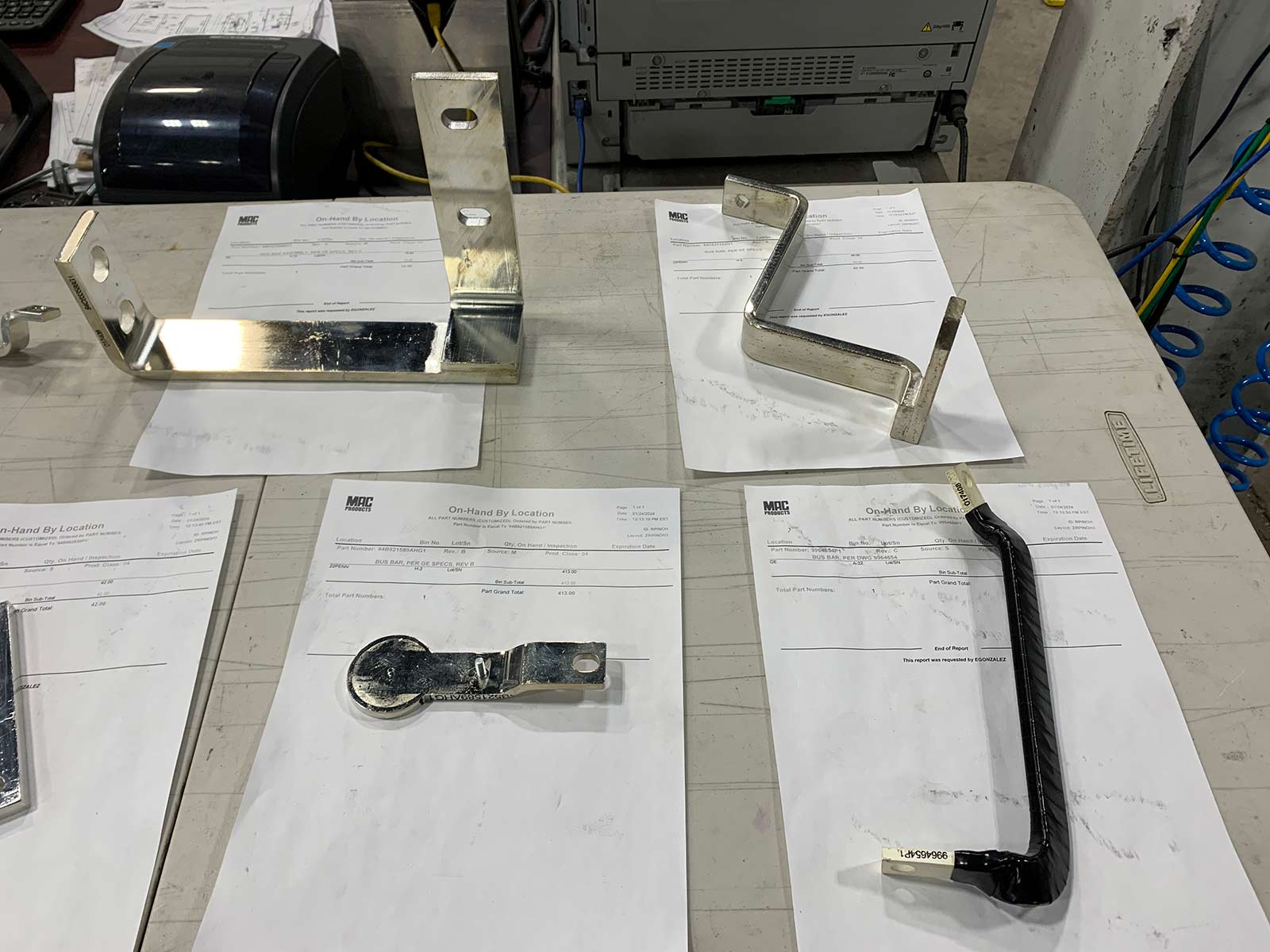

As a leading manufacturer of electrical components for the mass transit, rail, and utility industries, MAC was ideally situated to provide the copper busbars required for this project. Busbars are metallic strips that help to organize and distribute power by acting as a central conductor that connects various components within a system.

We have over 40 years of experience designing, testing, and manufacturing busbars, and our Engineering and Quality teams played a central role in assisting in the validation and qualification of these parts for the newly designed locomotive.

Manufacturing prototypes for a project such as this involves numerous challenges, the most significant of which occurred during the prototype integration of the newly designed busbars. 3D models made by the customer were intended to simulate this process; however, they had not sufficiently identified all of the space constraints.

This meant that MAC had to work with the customer to implement a number of changes in a short period of time. Fortunately, our ability to be agile and responsive ensured we were able to make the requested design changes in time for the project to be delivered on time and within budget.

Tried-and-Tested Solutions

Though this locomotive was the first of its kind, MAC was able to employ tried, tested, and proven technologies in bringing it to life.

Rapid Response to Challenges

When we encountered an unforeseen error during integration, we were able to pivot and redesign the components quickly to ensure the project remained on schedule.

End-to-End Support

MAC’s experienced team members were available to the customer at every stage of the project, from prototyping and designing through to installation, testing, and completion.